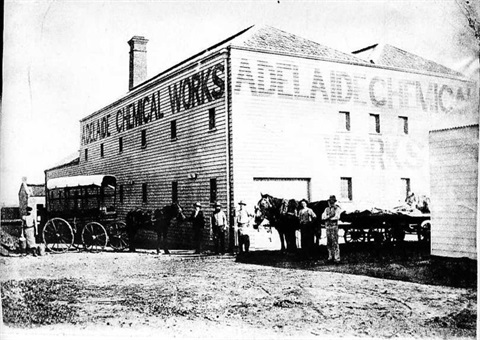

Adelaide Chemical Works (Torrensville)

In 1881, bouyed by the success of the Melbourne plant, Cuming sent his eldest son Robert Burns Cuming (1859-1910) to set up a similar factory in Adelaide - in South Australia both sulphuric acid and superphosphate had to imported at high tariffs from other Australian colonies or from overseas.

In late 1881 R.B. Cuming chose a rectangular 5.5 acre (around 2.22 hectares) site on the western side of Bellingham Street (renamed by the Thebarton council as a part of Jervois Street in 1937) New Thebarton Extension (which became a part of Torrensville from 1909) as the home for the venture.

The plant was constructed largely of wood since acid fumes would damage an iron structure. The site also featured eight furnaces and a chimney stack. The plant’s boiler and furnaces were made at James Hooker’s Hindley Street foundry.

The Adelaide Chemical Works Company began operation on 22 July 1882 – it was not only South Australia’s first chemical plant but one of only four in Australia. John Mossop was plant superintendent and head chemist.

At first the company employed only a handful of workers (and one horse) and concentrated on the manufacture of sulphuric acid and to a lesser extent acetic, carbolic, nitric and muriatic acids (the last a form of hydrochloric acid).

By the late 1880s the company was producing more than seven hundred tons of acid per year.

From mid-1884 the Adelaide Chemical Works ventured into the manufacture of artificial fertiliser by soaking bones with sulphuric acid, a mixture called Bone Super.

By 1896 the New Thebarton plant employed around fifteen men and in addition to its manufacture of acids and small quantities of superphosphate, produced a range of fertilisers including those based on liquid ammonia, iron sulphate and sodium nitrate.

The following year it rebuilt and doubled the size of its plant to 2.5 acres (around 1.01 hectares). Construction, by James King and Son of Hindmarsh to a design by Cuming, began in November 1896. Cuming asserted, probably accurately, that the brick plant was one of the most modern of its kind in the world. To reduce transport times the company also built a private road of around three hundred metres along the southern bank of the Torrens from the factory directly to Taylors Road (now South Road).

Cuming’s third child, also named Robert Burns Cuming (1887-1956), took over as manager and as a director of the Adelaide Chemical and Fertilizer Company Ltd after his father’s death.

In September 1911 the Adelaide Chemical Works bought 6.8 acres (around 2.75 hectares), to extend its holdings further west of Bellingham Street. In October 1920 and December 1923 the company bought an additional 1.72 acres (around 0.70 hectares) west of Bellingham Street, bringing its final land holdings at Torrensville to around 20.4 acres (around 8.26 hectares). The company’s land extended west along Ashwin Parade to just past West Street.

Before the coming of motor vehicles most of the land on the western side of Bellingham Street was used to stable and agist the company’s delivery horses: there were more than fifty in use in the early twentieth century.

By 1928-29, 4.25 million acres (around 1.721 million hectares) of land, 91.2% of South Australian agricultural land, was dressed with 172,000 tons of superphosphate. Total use around Australia was around 480,000 tons.

By 1940-41, 220,000 tons of superphosphate were being used in South Australia.

The story of the overwhelming acceptance of superphosphate was the same around Australia.